New fishing trawler – M/f Christina S

5th February 2024

Christina S FR 224

Impressive new Karstensens build joins Scottish pelagic fleet

Karstensens yard number 470, Christina S FR 224, was handed over to her new owners – a partnership between Freedom Fish Ltd, Shannon Fishing Ltd and Peter & J Johnstone Ltd – in mid-September. After a maiden landing of mackerel to Pelagia Liavag in Norway, she made her first UK landing to Pelagia Shetland at the very end of October.

The vessel was designed in-house by Karstensens, and follows the familiar lines of the series of advanced pelagic vessels delivered by the yard to owners around the North West Atlantic in recent years, combining energy efficiency, state of the art fish handling and storage facilities, and an exceptionally high standard of fit-out. The hull was built by Karstensen Shipyard Poland in Gdynia to Class DNV +1A Fishing Vessel E0 TMON; Ice-C. The hull was then towed to Skagen in February 2022 for outfitting. The new vessel replaces Fraserburgh skipper Allan Simpson’s previous command of the same name, and will operate along the same pattern as his previous vessel, pursuing a traditional pelagic trawl fishery targeting mackerel, herring and blue whiting. The previous 71.96m Christina S, which was built in 2008 by Norwegian yard Fitjar Mekaniske Verksted, has been sold to Icelandic fishing company Samherji and renamed Margrét EA-710.

The Simpson family has a long history in the industry, with Ernie Simpson taking command of his first new build in 1976. After heading the family business for five decades, he has now handed the reins to the next generation, with his son Allan Simpson now manager and skipper. The contract for the Christina S continued a working relationship between Karstensens and the Simpson family stretching back over 30 years, with the Sedulous and then three successive vessels named Christina S visiting the Skagen yard for repairs and maintenance. This, however, was the first time that they had worked together on a new build.

“Karstensen Shipyard highly appreciates the trust the owners have shown,” said the yard. “Returning and loyal customers is the best stamp any shipyard can get, as confirmation of its quality and business approach.”

The vessel design, specification and arrangements are the result of extensive and close co-operation between the owners and the yard, with all solutions tailored and optimised to suit their specific requirements. The vessel is fitted out with the latest machinery and equipment, with the focus on optimising working efficiency, safety and comfort for the crew, catch-handling and storage facilities, and fuel consumption.

The vessel has main dimensions of 77m LOA, length between perpendiculars 72.8m, breadth moulded 15.60m, depth to main deck 6.60m and depth to shelterdeck 9.20m. Her tonnage is 3,453GT. The 11 RSW tanks have a combined capacity of 2,350m3. Fuel oil capacity is 595m3 and freshwater capacity 100m3.

General arrangement

The hull of the new Christina S is built in steel with two continuous decks – main deck and shelterdeck – and long forecastle and boat decks. The wheelhouse, boat deck two, funnel and masts are constructed from aluminium. The hull is of round bilge construction, with a bulbous bow and stern skeg, flared stem and transom stern.

Below the main deck, the hull is subdivided into the following watertight compartments: forepeak, sonar room, thruster room, insulated RSW tank section with central RSW pump and manifold room, engineroom, and aftpeak with fuel and lube oil tanks. On the main deck, the arrangement from forward is: forepeak, storeroom and trunking for the retractable thruster, and the RSW hold/trunk section, with the vacuum pump room and RSW machinery room. Abaft the hold section, there is an accommodation area to starboard and a control room and engine store/workshop to port. Right aft is the hydraulic room with the steering gear.

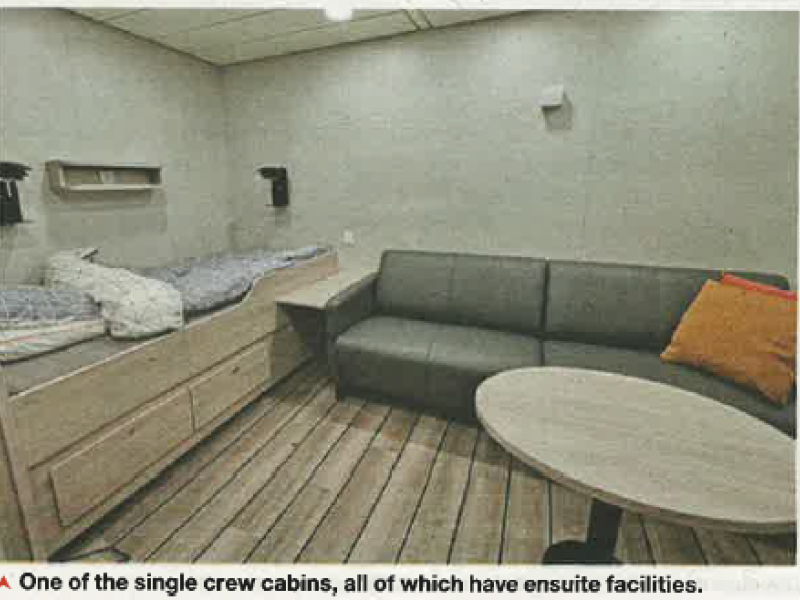

The accommodation on the main deck consists of three single and two twin cabins, all with ensuite facilities, and a laundry. On the shelterdeck, there is a storeroom in the forepeak and a generator room to starboard. Abaft of this is the enclosed loading deck, with the central deckhouse, the water separator and hatches for the 11 RSW tanks. Abaft midships is a full-width superstructure, with a corridor to port. The accommodation in the superstructure consists of four single crew cabins and a hospital cabin, all ensuite, a coffee bar, a changing room, a store for deck gear, and a large wellness area incorporating a gym and steam room. To starboard of the superstructure is the trawl workshop/store and an enclosed net store.

One of the net drums is located abaft of the superstructure at shelterdeck level. At the transom are the hydraulic stern gate and hydraulically operated guiding-on pins.

On boat deck one, abaft of the anchor winches are the roll reduction tank and the open deck. The superstructure/deckhouse forward of midships encloses the water separator and the sampling room.

Accommodation at this level comprises a day room/lounge, cinema, toilets, and the messroom and galley, with separate provision, fridge and freezer rooms. On the port side is a fan room for engineroom ventilation and the hydraulic pump room, as well as the exhaust trunks.

Abaft the deckhouse on boat deck one is the second net drum, the two drums being arranged in a waterfall configuration. Aft of the net drum are the two trawl winches. The tail-end winch is to port and the topline winch to starboard. Right aft on the port side are the fish pump and the hydraulic hose reel.

The trawl gallows is integrated into the aft vessel construction and boat deck one. This accommodates the two main towing blocks as well as the tailend and topline blocks. The net-sounder winch is fitted on top of the gallows.

On boat deck two, the deckhouse accommodation comprises six ensuite officer’s cabins, a laundry room and two instrument rooms. On the port side, aft of the deckhouse, is the Viking Norsafe Merlin 615 rescue boat and davit.

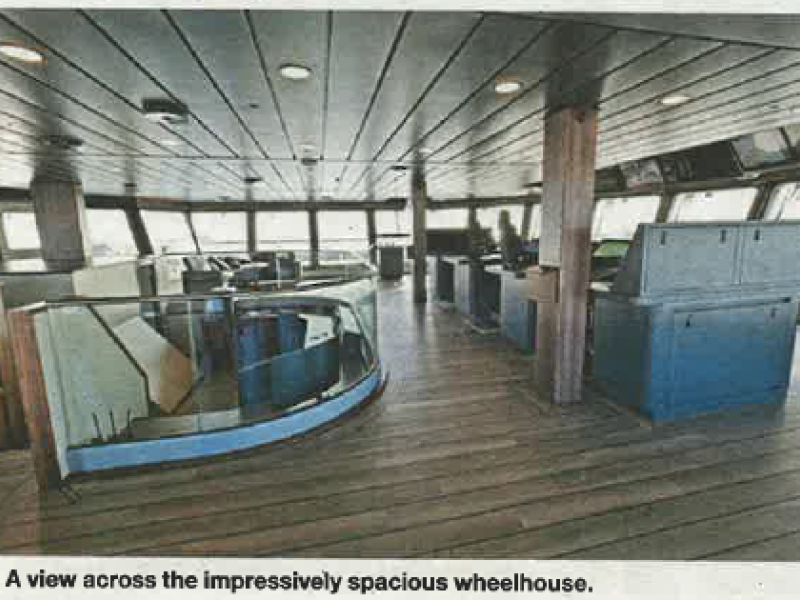

Finally, atop the deckhouse is the wheelhouse, with its windows providing 360° vision. The funnel is on the port side.

Engineroom

The Wärtsilä propulsion package features a 12V31 main engine of 7,320kW at 750rpm, driving a ducted 4,200mm 4G1190 propellor through a SCV 100/2-PDC68 reduction gearbox. The gives two fixed propeller speed steps of 138rpm and 116rpm. On sea trials, this propulsion package delivered speeds of 18.2 and 16.5 knots. A power take-off is mounted on the gearbox with a Cummins AvK 2,800kW/3,500kVA shaft alternator, producing 2,800kWe. To supply additional electrical power, the vessel is fitted with two Caterpillar C32 auxiliaries, each producing 940kWe at 1,800rpm. The harbour set is a Scania DI09 producing 200kWe at 1,800rpm.

During hauling and shooting, when the winch system is in use, the gearbox PTO will be clutched in, and electrical power will be supplied from the shaft alternator. When there is demand for full power from the deck machinery, there will normally not be same demand for power from the main engine, which allows it to be the primary power source for both propulsion and the hydraulic system. During normal towing, the shaft alternator will be disengaged, and electrical power will be supplied by either of the gensets.

The two main gensets are connected into the main switchboard, controlled by the vessel’s DEIF Delomatic power management system. A bus-bar breaker is fitted in the switchboard, allowing the Brunvoll FU-63 950kW/1,904hp aft thruster to be fed off the shaft alternator and the Brunvoll AR-63 850kW/1,999hp retractable thruster and vessel’s hotel load off the diesel gensets.

The electrical power system is fitted for sliding frequency (50-60Hz) by means of frequency converters for 400/440V and 230V. This allows the main engine and propeller rpm to be reduced by up to 17%. The vessel has Kongsberg Tenfjord SR 722 steering gear and a Kongsberg high-lift flap rudder. The pumps for main engine cooling, as well as the fuel transfer pumps and the deckwash, fire and bilge pumps, were supplied by Desmi, with the deck sump pumps coming from ITT Flygt. The box coolers are by Kelvion. The electrical contractor was KS Elektro, and the main switchboard was supplied and installed by ScanTechnic.

Deck machinery and RSW system

The hydraulic deck machinery package was supplied by SeaQuest Systems of Killybegs, and includes two 91t pull trawl winches, controlled by a SeaQuest autotrawl unit, a 71t topline winch, a 57t tail-end winch, two 110t net drums, nine 11t mooring winches, a 14.7t anchor windlass, a netsounder winch, two hydraulic hose reels and two fish hose reels. SeaQuest Systems also supplied the vessel’s two 20in fish pumps, as well as two foredeck cranes, the aft net crane and gallows crane, and the high-pressure drive systems for the winches, cranes, fish pumps and associated equipment.

Catches are pumped onboard and pass through the separator before being routed to the selected RSW tanks. The owners opted for a twin Johnson Controls RSW system, each of 1,506kW/1.295.000kCal/h, and a C-Flow vacuum system comprising two 4,200-litre tanks and four 87kW compressor units.

The four Azcue 525m3/h circulation pumps and two Azcue 300m3/h condenser pumps were supplied by Bombas Azcue.

Wheelhouse electronics

The extensive array of navigation, fishfinding and communications equipment on the new Christina S was supplied by Furuno UK and Woodsons of Aberdeen.

Facing a trio of Norsap 1600 skipper’s chairs, the Furuno Blue Bridge display system incorporates nine 55in, 14 32in and four 27in Hatteland display screens. There is also a control position aft, overlooking the trawl deck. The sonar units are all from Furuno: a low-frequency FSV-25, a medium-frequency FSV-85 and a high-frequency FSV-75. There are four echosounders: Simrad ES80, Furuno FCV-38, Furuno FSS3-BB and Furuno DFF-1. WASSP 80kHz 3D sonar is installed, along with a Furuno CI68 current indicator.

The vessel uses a Scanmar net-monitoring system and Simrad FS-70 trawl sonar. Navigation equipment includes Furuno FAR 3210-X, Furuno FAR 3230-S and Furuno DRS6D-NXT radars, and Furuno FMD-3200 ECDIS. The vessel has MaxSea TimeZero and Olex 3D plotters, Furuno GP-170 GPS and Furuno FA-170 AIS, two Simrad RGC-80 gyro compasses, and JRC JLR-21 and Furuno SC-70 GPS compasses. A Simrad AP70 autopilot system is installed, and the voyage data recorder is the Furuno VR-7000. The V-Sat and satellite TV systems are from Sailor, and a Vingtor Stentofon intercom system provides communications throughout the vessel.